Line Decoral

The Decoral surface finishing technology ensures a distinctive appearance for the coated surface.

Surface Finishing

The Decoral surface finishing technology ensures a distinctive appearance for the coated surface. This design effect is achieved by applying a special powder coating followed by the sublimation of ink from a transfer film, into which the coated item is placed. This film transfers decorations such as wood, granite, marble, or other unique patterns.

Why Choose the Decoral Line?

- All colors and films used are certified by Qualideco.

- This unique technology is designed for demanding aesthetic appearances, going beyond the use of standard powder coatings.

- Decoral technology guarantees coverage of the surface along the entire length of profiles or sheets, with mechanical resistance and high quality of color and gloss.

- There are practically no limits to creative design possibilities. The Decoral line is characterized by maximum quality and absolute precision in creating imaginative, abstract three-dimensional images.

Currently, this system is increasingly sought after in residential architecture.

The ALBIXON powder coating facility houses the largest Decoral line in the Czech Republic. We adapt to modern architecture, which is becoming increasingly demanding, and thanks to strict controls and processes, the resulting decor is unmistakable.

Decoral System is one of 16 companies within the Gruppo VIV group, which began its activities in 1973 with anodizing and later with powder coating. The company is continuously engaged in research, with its main focus on high-quality surface finishing of aluminum with perfect imitation of decors such as wood, marble, and granite. The DECORAL® system was patented in 1994, transforming the world of aluminum. The ecological aspect and versatility of the DECORAL® system significantly expand the possibilities for furniture manufacturers, architects, and designers, meeting the demands of even the most discerning customers.

Today, Decoral System is globally recognized as a LEADER IN THE DECORATION OF METAL OBJECTS. The company manufactures high-quality raw materials and technologically advanced equipment specifically developed for the sublimation process. With its own laboratory, Decoral-branded products are a guarantee of quality. Products are thoroughly researched and tested by certification companies that have issued the QUALIDECO trademark, ensuring the product's suitability for outdoor use with high resistance to weather conditions worldwide. Currently, DECORAL® facilities and products are present in 98 countries around the world, with over 600 installed systems.

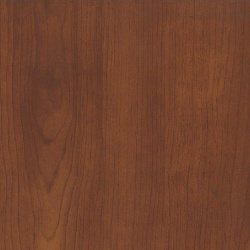

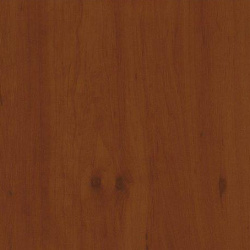

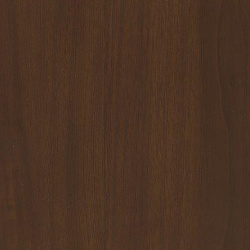

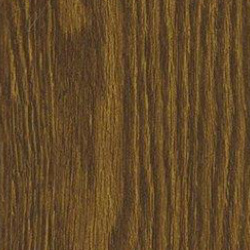

Decor and Its Patterns

Are you interested in new decorating options? You will surely be captivated by our wide range of decors that we can create for you. Using the Decoral line, we can decorate profiles with various unique patterns. You can choose from decors that mimic wood, marble, granite, PVC, and more. With our surface finishing, you will definitely be satisfied. Our offering includes both standard patterns and less typical, very modern designs. When decorating, you can select not only the pattern but also a specific color shade. You will be pleased with our services.

Surface Decoration

We offer professional-level surface decoration. Thanks to our specialized equipment—the Decoral line—we can process profiles up to 9 meters long and flat materials up to 5 meters in length. If you need assistance in choosing the right decor, feel free to reach out to our staff. We are specialists in decorating any surface. Choose from our extensive range of decor patterns. Among the favorites in our offering are wood imitation decors, which are very popular with customers.

Standard Patterns

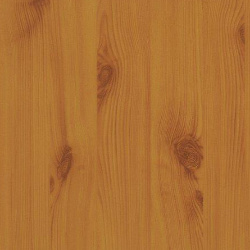

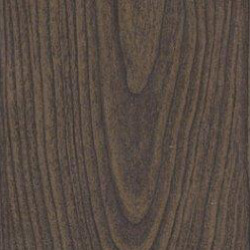

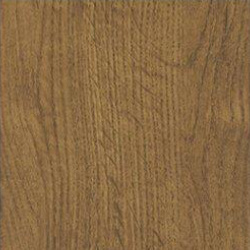

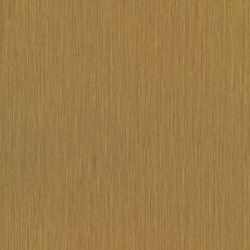

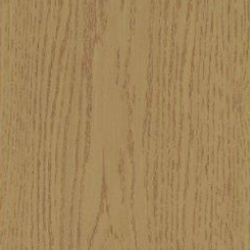

Pine

Beige Beech

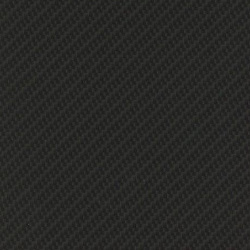

Carbon

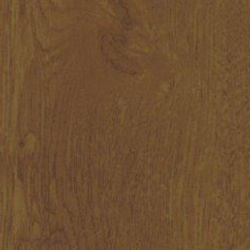

Douglas N8

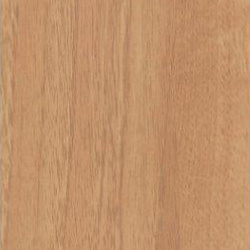

Natural oak

Roma oak

Grey oak

Shire oak

Summer oak

Light oak

Winer oak

Golden classic

Grey pine

Maple

Elm

Calvados

Chestnut

Alder

Walnut

Rovere

Rustic

Light teak

Dark teak

Datk Brown Oak

Cherry

Golden oak

Decoral® Process

The Decoral manufacturing company specializes in decorating aluminum profiles and sheets at a temperature of 200 °C, utilizing sublimation for the decoration process. Sublimation is a chemical-physical process in which a substance transitions from a solid to a gaseous state without passing through a liquid phase.

Decoral Process in Practice

To decorate items, we need the following:

- Decoration Equipment

- Special Polyurethane Paint with sublimation properties

- Transfer Foil printed with sublimation ink

Technological Procedure:

-

Preparation: After suitable pre-treatment, a base layer of electrostatically applied polyurethane powder paint (60-90 microns thick) is coated onto the metal object and baked at 200 °C.

-

Cooling and Foiling: After cooling, the item is wrapped in sublimation ink foil and placed on a frame from which all air is evacuated. This vacuum ensures the foil adheres perfectly to the surface of the item.

-

Sublimation: The frame is transferred to the oven, where the ink penetrates the baked layer of powder paint at 200 °C, resulting in a perfect decorative finish.

-

Final Steps: After removing the frame from the oven, the item is air-cooled, and the ink-free foil is easily peeled away.

How Does the Decoration Process Work?

-

Selection of Decor: The customer selects a decor, which consists of a base polyurethane powder paint and a special foil containing the desired pattern. The surface structure can be either smooth or have a fine texture, determined by the selected base powder color.

-

Powder Coating: The material must first be powder coated, which includes chemical pre-treatment, drying, powder application, and baking.

-

Decoration: The decorated material is placed in a "sleeve" made of Decoral foil. This foil contains ink and the corresponding pattern, ensuring the final effect when combined with the polyurethane powder paint. The thermal transfer occurs at approximately 200 °C for about 15 minutes on the Decoral line.

-

Post-Processing: After exiting the Decoral line, the operator removes the foil, which is now pattern-free and cannot be reused. The item is then inspected, packaged according to customer preferences, and prepared for dispatch.

Decoration Options

Almost any item made from aluminum or iron can be decorated, but our company primarily focuses on aluminum profiles.

- Profile dimensions: 900 x 190 x 30 cm

- Sheet dimensions: 300 x 100 cm